So you’ve heard about our slope top lockers beginner blog and you’re ready to start choosing the perfect slope top to complete your new design? Welded slope tops and continuous slope tops each offer different benefits to the user and to the space. So why would a customer choose one over the other?

Structural Integrity

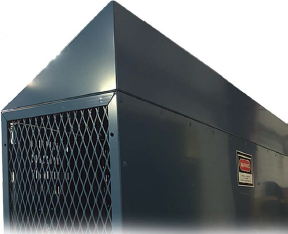

Welded slope tops are by far the sturdier option. Usually made of thicker steel and more securely bonded to the locker, these can easily withstand backpacks and other objects being thrown at them, and don’t easily dent. Continuous slope tops, on the other hand, have the potential to bend over time if objects are thrown, and may even show marks.

Welded slope tops are finished and inspected by the manufacturer, too, which could provide additional quality and consistency, compared to continuous slope tops that are installed on site by various contractors with different levels of time and attention.

Appearance

For some customers, it’s important to have a well-finished look to the lockers. The continuous slope top doesn’t have as many breaks as the welded, being made from a single piece of steel. The spliced plate looks like one continuous run and has far fewer defined markings.

For some customers, it’s important to have a well-finished look to the lockers. The continuous slope top doesn’t have as many breaks as the welded, being made from a single piece of steel. The spliced plate looks like one continuous run and has far fewer defined markings.

On the welded slope top, you can see the breaks where the pieces have been bonded together. In this case, it is a trade-off between security and aesthetics, and it all depends  on what matters more to you.

on what matters more to you.

The standard angle for continuous slope tops is 18 degrees, while 25 degrees is typical for welded slope tops. The steeper angle is a little easier to clean, harder for any dust to accumulate, and harder to put objects on top of. Even this small difference can affect the appearance; it appears either sharper or milder.

Installation Time

Not all job sites have tons of time available for locker installation, which can be another factor in the final decision. Continuous slope tops have to be cut and installed in the field, which increases the total install time. But a factory attached slope comes ready to be installed, resulting in a shorter on-site installation. Check out the links below for a time-lapse video on both installations.

Factory Attached Slope Top Video

Matching the Locker

Knock down lockers are those that are delivered in parts to be assembled by a trained team on-site. Continuous slope tops are always used for this type of locker, since the locker runs and numbers aren’t confirmed until after installation, and the continuous slope tops allow for customization at the last minute.

Welded lockers come in fully assembled units and are furnished with welded slope tops if desired. Continuous slope tops can be requested instead, in which case they will be attached on-site after installation.

Material

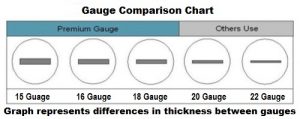

The thickness of steel used to make lockers and slope tops is measured in ‘gauges’, and the lower the number the thicker the steel. For instance, 20-gauge steel is thinner than 15 gauge steel.

Continuous slope tops are typically made with 20-gauge steel, but it is common to upgrade to 18 gauge. Welded slope tops are made in 18-16 gauge, making the structure more heavy-duty and much stronger. Still, the construction is what gives a slope top its agility and is more important than the actual gauge of the steel. So an 18-gauge welded slope top will still be stronger than a 16-gauge continuous slope top because the structural integrity of the welded is stronger.

Cost Difference

When it comes down to pricing, welded slope tops end up being 8-10 percent more expensive than continuous. More steel goes into manufacturing these and the cost of additional materials and labor are factors.

How Can I Order?

Do you know which kind of slope top will work best for your lockers? Be specific about the details when contacting the manufacturer.

- “Continuous slope top” is fairly industry standard, while “welded slope top” can also be interchanged with “four-sided unitized” or “factory attached”.

- Specify the gauge of steel you want, typically 20-, 18-, 16-gauge steel for either welded or continuous slope tops.

- Let the manufacturer know if you have express requirements. If you don’t spell it out you’ll get the most basic version.

If you don’t know what kind of slope top will work best for your lockers, let us help!

DeBourgh takes pride in delivering the highest caliber lockers to its customers and is ready to help you figure out what will work best for you.